Air-blown fiber optic cables sometimes referred to as blown fiber optic cables or air-blown fiber (ABF) cables are a specific method of using fiber optic technology in communications infrastructure. These cables are made up of incredibly tiny optical fibers contained in air-blown tubes and covered in a protective covering. These air blown fiber optic cable stand apart because of the way they are installed. Rather than pre-installing the fibers, a pneumatic mechanism is used to force the fibers via microducts or pre-existing routes.

The fibers are guided through the tubes by nitrogen or compressed air, enabling quick and effective deployment. This technology makes it a preferred option for telecom networks seeking quick and flexible deployment solutions with high flexibility, scalability, and ease of future network extension or modification.

Basic Construction of Blown Fiber Optic Cables

Air-blown fiber optic cables, which are made to be easily installed, flexible, and scalable, are a sophisticated development in telecommunications infrastructure. These cables' distinct qualities and functionality in contemporary networks are mostly determined by their basic design.

Fundamental Elements of Fiber Optic Air-Blown Cables

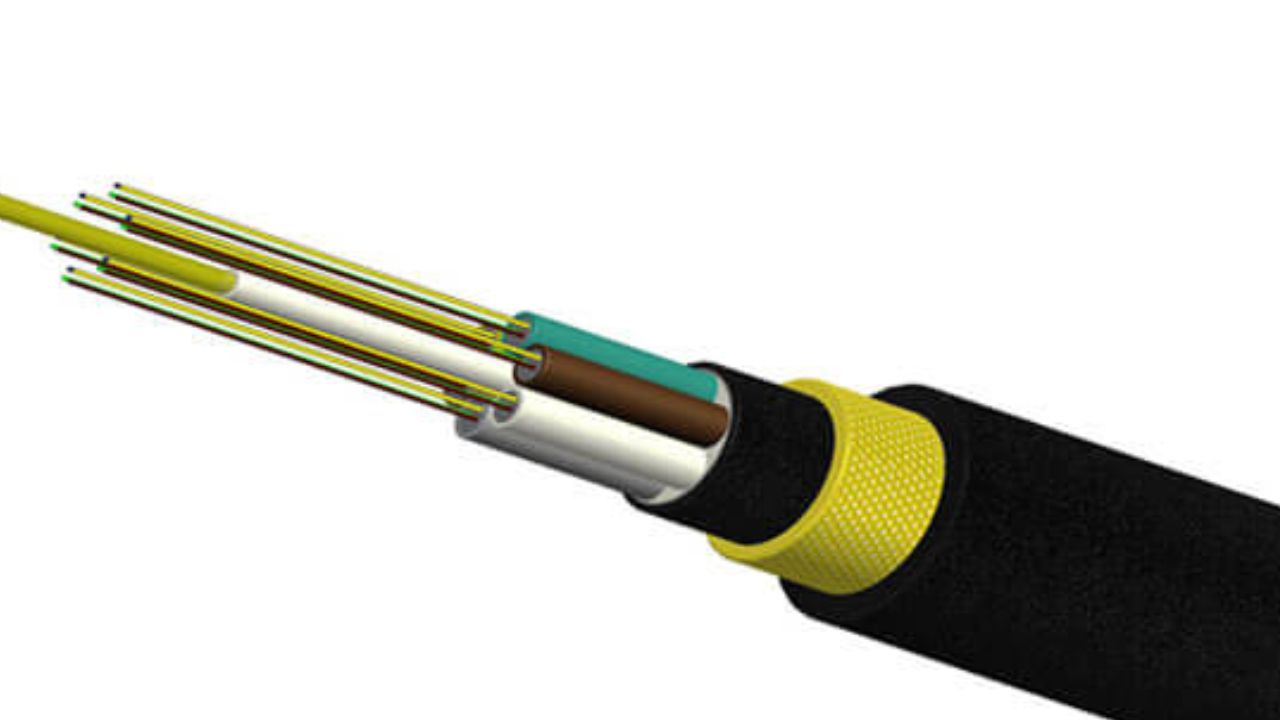

Air-blown fiber optic cables are made up of a few essential parts that are essential to their structure and operation. Typically composed of glass or plastic, optical fibers are the central component of these cables. Light pulses are transmitted across these wires carrying data. Compared to standard cables, the fibers in air-blown fiber cables are usually thinner and more flexible, making installation simpler.

A buffer or coating is put around each sensitive optical fiber to prevent damage. This improves robustness and endurance against outside influences by acting as a protective layer. The air-blown tube, a tube inside the cable where fibers are inserted, is the unique characteristic that sets air-blown fiber cables apart. This tube is made to make it possible to install using nitrogen or compressed air.

Concept of Air-Blown Tubes

An essential component of the design is the air-blown tube. It is specifically designed to make installation easier. During installation, the fibers are able to travel freely within the tube since it is often made of low-friction materials like polyethylene.

A lubricant is applied to the inner surface of the air-blown tube to lessen resistance and friction while the fibers pass through it. The effective and seamless installation of the fibers depends on this lubricant.

Coverage and Defense

Because they are easy to deploy and can easily adapt to a variety of situations and paths, air-blown fiber optic cables provide improved network coverage. Because of their reduced footprint, they are less prone to physical damage and cause less disruption during deployment, providing a strong resistance against wear and tear. Microducts and pneumatic blowing are dependable options for safe and effective network expansion since they also offer extra protection by lowering the possibility of illegal entry or tampering.

Accessory for Installation

Specialized installation accessories, such as micro ducts, connectors, and tools made specifically for the air-blowing process, are included with air-blown fiber cables. These add-ons guarantee flawless installation and are essential for controlling the setup in various networking contexts.

Air-Blown Installation Methodology

Pneumatic tools are used during the installation of air-blown fiber cables to force the fibers through the pre-installed micro ducts. By forcing compressed air or nitrogen via the microducts, the fibers are propelled into the intended route.

Advantages of the Building

Air-blown fiber optic cables' distinctive design has several benefits. They are very adaptive to changing network requirements because of their design, which makes upgrades and alterations simple. By utilizing air-blowing technology, installation can be completed quickly and easily, saving money on labor and deployment time. Air-blown fiber deployments create less interruption to the current infrastructure than standard cable installations, which makes them appropriate for network upgrades or retrofits. Because of their intrinsic design flexibility, air-blown fiber cables are prepared for future technological developments.

Final Thoughts

Air-blown fiber optic cables are made with a basic construction that demonstrates a smart and purpose-driven design that prioritizes adaptability, flexibility, and ease of installation. The reliable infrastructure made possible by this advancement in cable technology can easily handle the changing needs of contemporary communication networks.